A Concrete Batching Plant is a machine to manufacture Concrete from its ingredients viz Cement, Crushed Stone, Sand, Water and Admixture Chemicals. Sometimes additives like GGBS (Ground granulated blast Furnace Slag), Fly Ash or Micro-silica are added to change the characteristics of the end product. The word Batching Plant comes from the word "Batch", which essentially means that concrete is manufactured in measured bathes inside a Concrete Batching Plant.

There are 2 general methods of producing concrete: wet-batching and dry batching. Wet-batching is a process whereby concrete is mixed at the plant and is then transported to a job site where it's poured. The concrete may also be mixed and poured into molds on-site to create pre-formed products such as concrete pipes, slabs, and beams. Dry-batching is a process whereby concrete components are loaded into a truck mounted mixer and then subsequently mixed by the truck enroute to a job site where it is poured. An alternate form of dry-batching is the loading of concrete components into separate bins on a truck where the components remaining unmixed until they are offloaded at the job site.

Types of Concrete Batching Plant

Stationary and Mobile Concrete Batching Plant

Concrete batching plants, generally, are divided into stationary concrete plants and mobile concrete plants. This is a basic classification that many manufacturers distinguish at the time of production. Most of the stationary batching plants adopt the modular and splicing design, which is mainly used for large-scale commercial concrete manufacturers or related manufacturers of concrete components. It usually applies in large-scale engineering construction, owning the features of strong production capacity and stable anti-interference. The mobile batching plant is towed by a towing unit, which has good maneuverability and makes the production more flexible. It generally uses for various small and medium-sized temporary construction projects. Besides, it can be rented for personal use.

Central Mix and Truck Mix Concrete Batching Plant

A truck mix plant combines all ingredients except for water at the concrete plant. This mixture is then discharged into a ready mix truck (also known as a concrete transport truck). Water is then added to the mix in the truck and mixed during transport to the job site. A central mix plant combines some or all of the above ingredients (including water) at a central location. The final product is then transported to the job site. Central mix plants differ from ready mix plants in that they offer the end user a much more consistent product, since all the ingredient mixing is done in a central location and is computer-assisted to ensure uniformity of product.

How does the Concrete Batching Plant works

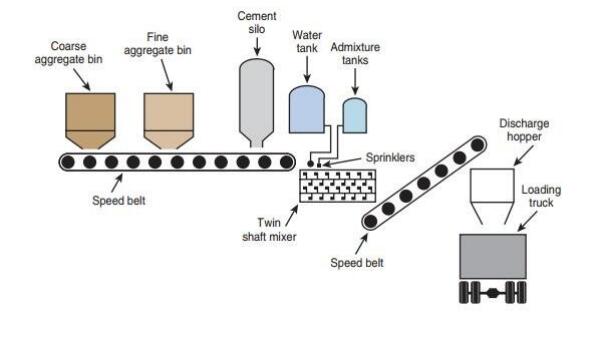

Concrete batching plant is divided into four parts: gravel feed, powder (cement, fly ash, bulking agents, etc.) to feed, water and feed additives, transmission and storage stirred their work flow shown in Figure 1 , the mixer control system power, into the human – machine dialogue operation interface, system initialization process, including recipe number, grade concrete slump, producers, etc. according to the amount of weight carried on each silo, weighing hoppers. detection, output material or material empty full signal, prompting the operator to determine whether to activate the control program starts stirring sand, stone belt motor fed into the metering hopper; open fly ash, cement tank valve, start the electromagnet screw conveyor ash cement to the metering hopper; open water reservoir and control valves admixture pool water and additives into the metering hopper metered meet the set requirements doo door open metering, mixing the ingredients into the mixer within already started to set. time to open the mixer door, into the concrete mixer had received material.

Components of Concrete Batching Plant

Concrete Mixer

Concrete Mixer is the most critical part and heart of the concrete batching plant. The job of the mixer is to receive all the ingredients and mix them thoroughly for a fixed time. Then it will discharge the contents into a transit mixer or a concrete pump.

Aggregate weigh conveyor

Weigh conveyor usually sits below the aggregate feeders. It is suspended and hanging on load cells. It is to weigh aggregates one by one and then transfer the same to charging conveyor of skip. Aggregates are discharged to the weigh conveyor by opening and closing of pneumatic cylinders.

Cement silo / hopper with screw conveyor

Cement silos are an indispensable device in the production of concrete. It mainly stores bulk cement, fly ash, mineral powder and others. Camelway offers concrete production solutions, helping customers evaluate project requirements to select the right powder storage equipment. A screw conveyor of suitable diameter and length is at the bottom enabling transfer of cement into the cement weigh hopper. Many small capacity machines are equipped with a cement hopper. The opening of the hopper is big and it facilitates adding of cement that comes in bags. Bags have to be placed on top of the hopper and once they are torn, cement will fall into the hopper. Cement hoppers are also provided with screw conveyor for transfer of cement into the weigh hopper. Usually a weigh hopper has 2 openings on top for inlet of 2 screw conveyors.

Control System

Control system will control the working of the machine. Latest machines are equipped with PLC panel for ease of usage. It is also possible to save and print mix material recipes in the latest equipment. Control panel assist in fast and accurate measurements of the ingredients. With growing demand for high quality and accurate concrete it becomes important to produce quality material without any wastage. This is where control panel helps to control all components of the batching plant.

Concrete Batching Plant Capacity

Concrete Batching Plant capacity is an important indicator to measure the size of a concrete batch plant, it also a factor that effect the price of batching plant. "concrete batching plant capacity" describes how many concrete of the batching plant can be produce per hour or per batch. In most circumstances when we talk about the capacity of a concrete batching plant, we means how many cube concrete of the concrete batching plant can produce per hour, for example, a HZS90 concrete batching plant's capacity is 90 cube meters per hour.

Concrete Batching Plant Price

Usually, if the customer request a sample price list from concrete batching plant manufacturer, the will be gived a price range of a concrete batching plant, because when someone need to buy a concrete batching plant, there will be many details need to be determined for the price list. The following table shows the price of concrete batching plant in 2017 of camelway machinery.

| Model | Capacity | Price(US Dollar) |

| HZS25 | 25m³/h | $27,000 |

| HZS35 | 35m³/h | $35,000 |

| HZS50 | 50m³/h | $38,000 |

| HZS75 | 75m³/h | $44,000 |

| HZS90 | 90m³/h | $60,000 |

Concrete Batching Plant Manufacturers

When customer plan to buy a concrete batching plant, they usually need to get quotes from several different suppliers. I'd like introduce to some famous concrete batching plant manufacturers here for your referrerence, names not listed in order.

1, Henan Camelway Machinery Manufacture Co.,Ltd

Camelway Machinery is realy an old company which founded in 1983, foucus on manufacturing concrete mixing plant, twin shaft mixer, aggregate bins, etc. Camelway Machinery is family owned company, annual sales of about 30 million US dollars. Camelway Machinery is not a very big company, but everyone in this company are foucus on do better work, so more and more customer recognize us. We have expanded our international business since 2005, before December 2018 customers in more than 100 countries around the world have chosen our concrete batching plant. our concrete batching plant include stationary, mobile, temporary and continues type, you can click here for more of our concrete batching plants.

2, Liebherr-Mischtechnik

A German company that has a very broad business scope, concrete batching plant as one of their bussiness which include compactmix, betomix, mobilemix and metomat type. As a old and large company, many big company chose them as supplier

3, BMH System

A Belgium company founed in 1990, they have wet, dry and mobile concrete batching plant, I am not faimlier with this company, but some of our customer choice this company.

4, ODISA

A Company Located in Mexico, which concrete batching plant include transimit mix and central mix type. As a Manufacturer in Latin America, some customers choice this company.

5, Apollo Inffratech Pvt. Ltd.

One of India’s largest manufacturers of high quality concrete construction equipment, which concrete batching plant include dry batching plant, mobile batching plant, etc.

6, McCrory Engineering

A British company, Located in 49b Armaloughey Road, Aughnacloy Co. Tyrone Northern Ireland BT69 6DN, which has 25 years of experience supplying the UK and Ireland’s largest concrete companies. Concrete Batching Plant include Mobile Concrete Batching Plant, Mobile Cement Silo, Static Concrete Batching Plant, etc. Customer include lafarge, marshalls, lagan, hanson, etc.

![]() what-is-a-concrete-batching-plant.pdf

what-is-a-concrete-batching-plant.pdf